3D printing is a revolutionary technology that has changed the way we manufacture products. It has a wide range of applications in various industries, including aerospace, automotive, healthcare, and education. In this blog post, we will discuss 3D printing and its types.

What is 3D printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital model. The process involves creating a virtual model of the object using computer-aided design (CAD) software and then converting the digital model into a physical object using a 3D printer.

Types of 3D printing

There are several types of 3D printing technologies available, each with its unique approach and benefits. Here are the four most popular types of 3D printing technologies:

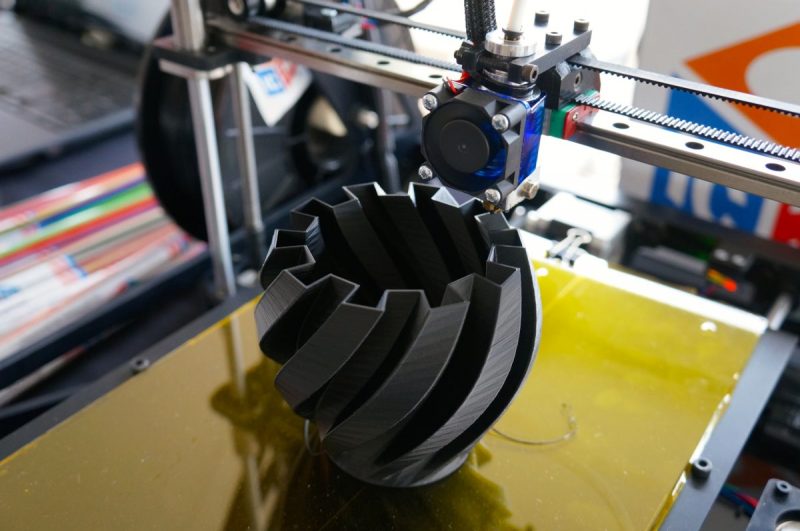

1. Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most common and widely used 3D printing technology. It works by melting a thermoplastic filament and extruding it layer by layer to create a 3D object. FDM is popular because it’s easy to use, affordable, and can print with a variety of materials, including PLA, ABS, PETG, Nylon, and more. The printed parts can be strong and durable, making FDM ideal for prototyping and low-volume production.

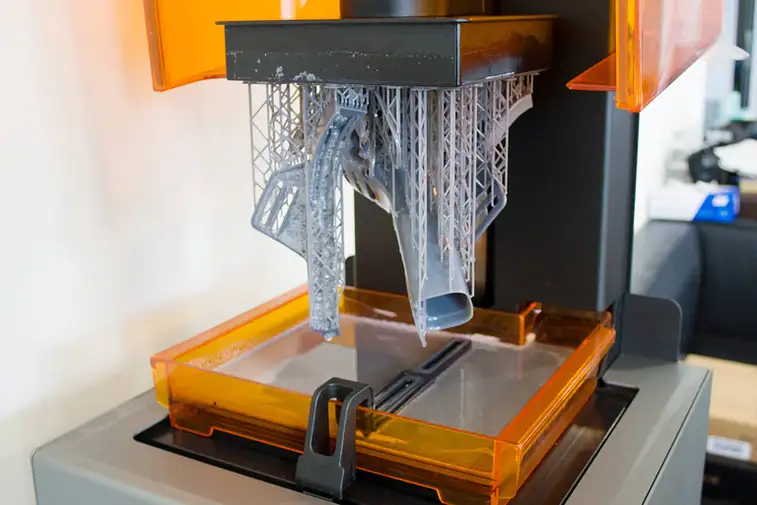

2. Stereolithography (SLA)

Stereolithography (SLA) is a 3D printing technology that uses a liquid photopolymer resin that is cured with a UV laser to create a 3D object. SLA is popular because it can create parts with high detail and accuracy, making it ideal for creating small parts, jewelry, dental models, and more. However, SLA parts can be brittle and not as durable as those created with FDM.

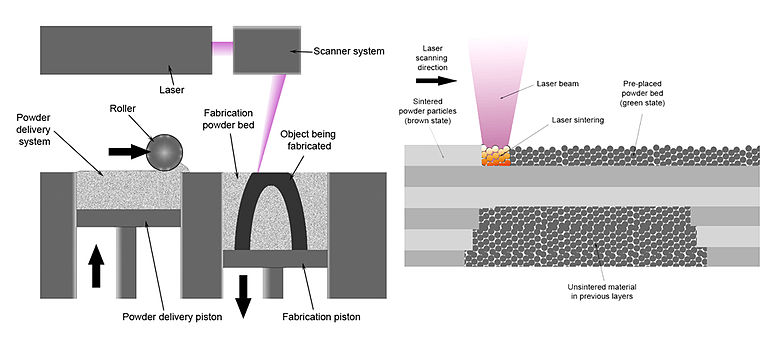

3. Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a 3D printing technology that uses a laser to sinter a powdered material, such as nylon or polyamide, to create a 3D object. SLS is popular because it can create parts with high accuracy and can print with materials that are not available for FDM or SLA. SLS is ideal for creating complex geometries, such as interlocking parts or lattice structures. However, SLS is more expensive than FDM and requires specialized equipment.

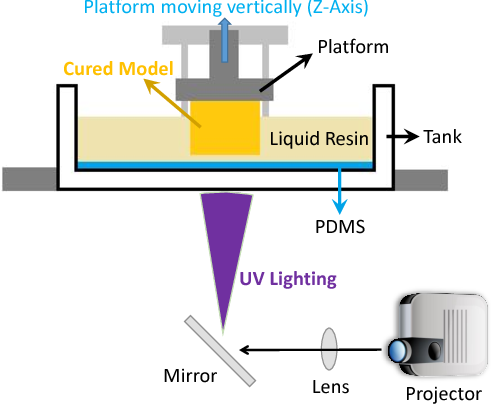

4. Digital Light Processing (DLP)

Digital Light Processing (DLP) is a 3D printing technology that uses a light source to solidify a liquid photopolymer resin layer by layer. DLP is similar to SLA but uses a different process to cure the resin. DLP is popular because it can create parts with high detail and accuracy, making it ideal for creating small parts, jewelry, and dental models.

Conclusion

3D printing is a rapidly growing technology that has revolutionized the manufacturing industry. There are several types of 3D printing technologies available, each with its unique benefits and limitations. Choosing the right type of 3D printing technology will depend on the specific needs of your project. FDM is the most popular and widely used technology because it’s affordable, easy to use, and can print with a variety of materials. SLA, SLS, and DLP are ideal for creating parts with high accuracy and detail or with specialized materials.

An interesting discussion is definitely worth comment. I do believe that you should publish more about this subject, it may not be a taboo matter but typically people dont discuss these subjects. To the next! Many thanks!!

Im very happy to uncover this site. I wanted to thank you for ones time for this particularly wonderful read!! I definitely appreciated every bit of it and i also have you book marked to see new information in your site.

A motivating discussion is worth comment. I believe that you ought to write more on this topic, it may not be a taboo matter but generally people do not talk about such issues. To the next! All the best!!

Good post. I learn something totally new and challenging on blogs I stumbleupon on a daily basis. Its always useful to read content from other authors and practice something from their websites.